Quick summary: Automotive heat insulation is not just “adding a heatshield.” Reliable thermal control comes from the right material, correct spacing, and installation that survives vibration and thermal cycling. This guide covers exhaust pipe thermal insulation, turbo heat shield, catalytic converter heat shield, intake heat shield, and common car heat shield design mistakes.

Exhaust temperature control: Exhaust Insulation Solutions | Hose/wire protection near heat: Fire Sleeve | Local barriers and edge protection: Heat Shield Tape | Technical PDFs: Download Technical Documents

Modern powertrains pack hot components into tight spaces. Without the right automotive heat insulation, radiant heat and heat soak can increase underhood temperatures, shorten hose/wire service life, raise intake air temperature, and create hot spots near plastics and composites. A proper automotive heat shield strategy focuses on four targets:

In automotive thermal management, “heatshield” is often used broadly. In practice:

For severe zones, the most reliable approach is to reduce heat at the source and then shield sensitive components. Start with exhaust insulation solutions, then use targeted shields where needed.

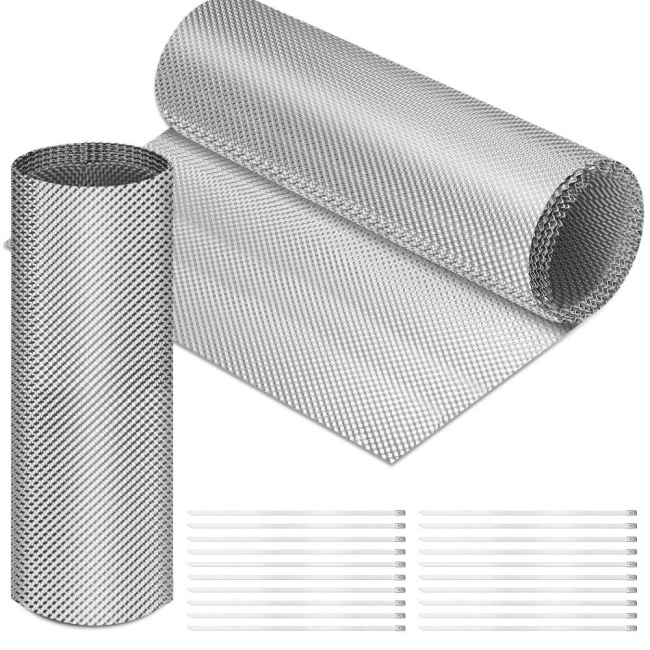

Exhaust pipe thermal insulation aims to reduce surface temperature and radiant heat from hot pipes. It is especially effective in tight packaging areas where a conventional stamped car heat shield cannot maintain enough air gap. Key selection factors:

If your routing includes hoses or wiring near hot zones, add dedicated protection such as fire sleeve to prevent heat-related aging and reduce risk at critical points.

A turbo heat shield targets one of the highest heat sources in the engine bay. Reliable turbo shielding typically requires:

When turbo surface temperatures are extreme, shielding alone may not be enough. Consider combining a shielding approach with source insulation solutions to reduce radiant output and stabilize surrounding component temperatures.

A catalytic converter heat shield is commonly used to protect underbody components and reduce heat exposure near floors, fuel lines, and surrounding plastic/trim. Underbody shields must handle water spray, salt, debris impact, and continuous vibration. Best practices include:

For localized sealing and edge reinforcement where applicable, consider heat shield tapes and barriers.

An intake heat shield focuses on reducing heat soak and stabilizing intake air temperature by shielding the intake path from nearby heat sources (exhaust manifolds, turbo, radiators). The goal is not only protection but also more consistent performance. Selection rules:

If you are building a complete thermal strategy, combine intake shielding with exhaust-side temperature control using exhaust insulation solutions.

Not exactly. An automotive heat shield blocks radiant heat and protects adjacent parts, while exhaust pipe thermal insulation reduces heat at the source. In severe heat zones, combining both usually delivers the most stable results.

A turbo heat shield is most effective when it preserves spacing, stays secure under vibration, and is paired with a broader exhaust thermal plan. For very high heat loads, consider source insulation solutions.

Use dedicated hose and cable protection such as fire sleeve protection where routing is close to hot components. For localized edge reinforcement, use suitable heat shield tapes and barriers where applicable.

Yes. For many products we provide datasheets and technical PDFs. Visit Download Technical Documents or request a document pack through Request a Quote.

Share your vehicle platform, heat source location (exhaust/turbo/catalyst/intake), clearance, mounting method, and target temperatures. We will recommend a practical heatshield and insulation approach and provide supporting technical documents.